Henan Rentai Boiler SCADA

Henan Rentai Electrical's boiler SCADA is a powerful tool that helps your equipment maintain high-efficiency operation. It adopts a familiar Windows style design, with an intuitive and user-friendly interface, provides rich real-time data and historical trend information, and can easily access process cycles and alarm controls. It also uses the most advanced technology and has stable and reliable characteristics.

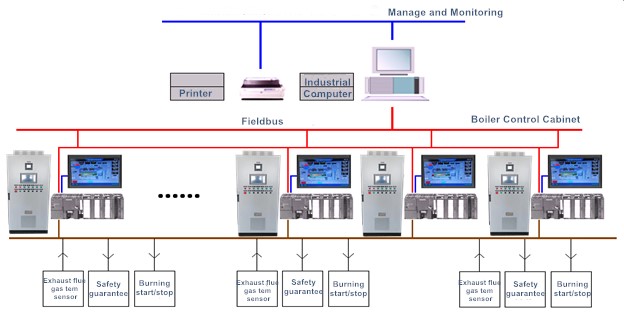

This system is a stand-alone system specially developed for industrial boiler rooms and power plants. Our business scope usually covers the monitoring and supervisory control of multiple boiler equipment, combustion devices, heat exchangers, deaerators, buffer tanks and pumps.

Advantages of the Henan Rentai Boiler SCADA

Plant-Wide Control and Monitoring: Enables monitoring and management of the entire plant from any desktop location.

High Scalability: The system architecture is designed to accommodate future technological upgrades and expansion needs.

Redundancy Options: Ensures continuous system operation, minimizing downtime to the greatest extent possible.

Strong Compatibility: Communicates with most controllers available in the market, utilizing non-proprietary software for maximum flexibility.

Remote Operation: Supports remote access, enabling monitoring and management anytime, anywhere.

Real-Time and Historical Trend Analysis: Provides valuable insights to operators, helping optimize production processes and improve efficiency.

Boiler SCADA Configuration

Hardware Configuration

SCADA System Platform:Operates on a DELL industrial computer equipped with robust performance capabilities.

Peripheral Devices:

At least 22-inch high-definition monitor for clear visualization.

Standard keyboard and mouse for user interaction.

Laser color printer for printing trends, reports, and alarms.

Uninterruptible Power Supply (UPS) for surge protection and to handle brief power failures.

Software Configuration

Core System Platform: Developed on SIEMENS WinCC 7.4 platform, ensuring high reliability and robust performance.

Supplementary Software and Features:

HP Printer for automatic printing of operational log tables.

Automatic report generation on a daily, monthly, and annual basis.

Information storage in a database, with linkage to spreadsheets for easy viewing and analysis.

This configuration ensures efficient operation, seamless data handling, and reliable monitoring and control of the boiler group system.